Report: Engineering the Future of Distributed Manufacturing

For the engineering research community to lead in changing the trajectory of U.S. manufacturing, it is essential to identify, scale up, and integrate critical technologies for new and emerging advanced manufacturing sectors to create a secure, resilient, and adaptable manufacturing ecosystem. Doing so will contribute to a more flexible and secure economy in the 21st century and beyond.

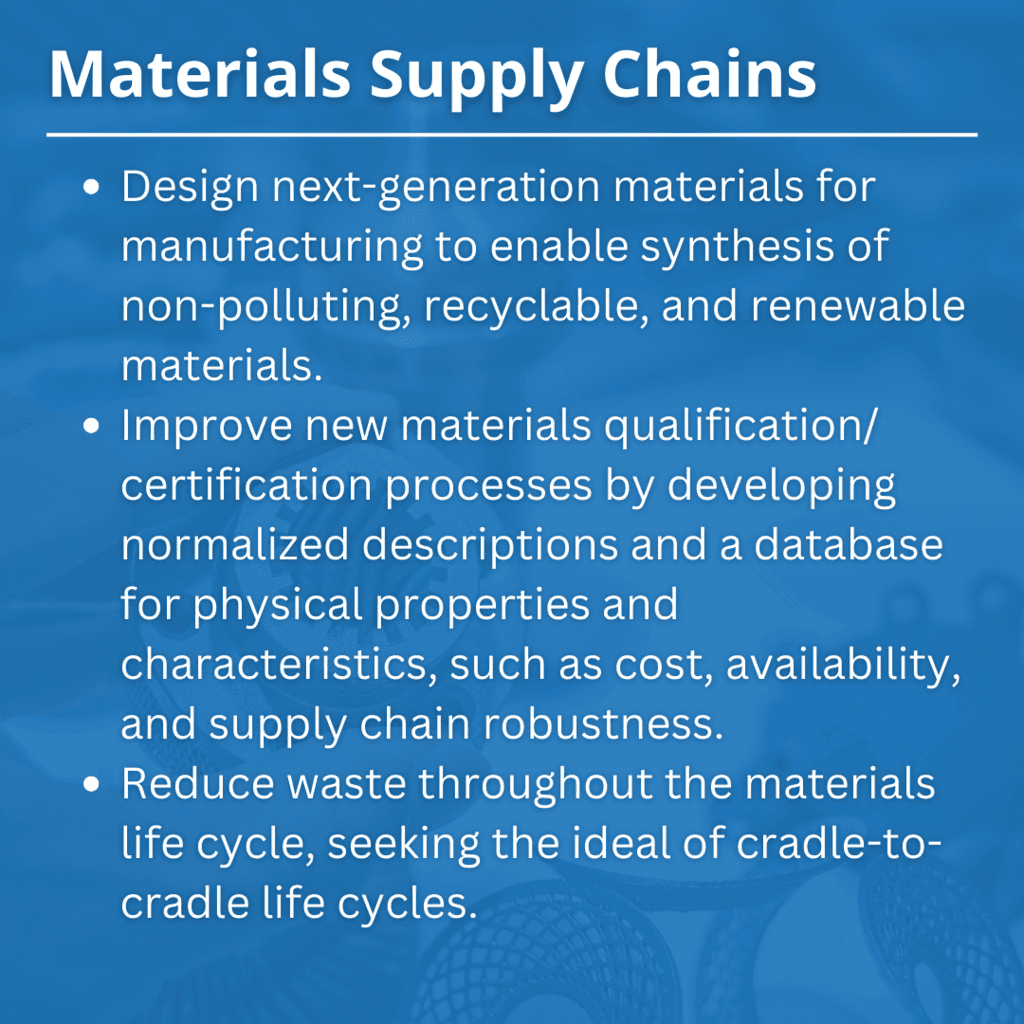

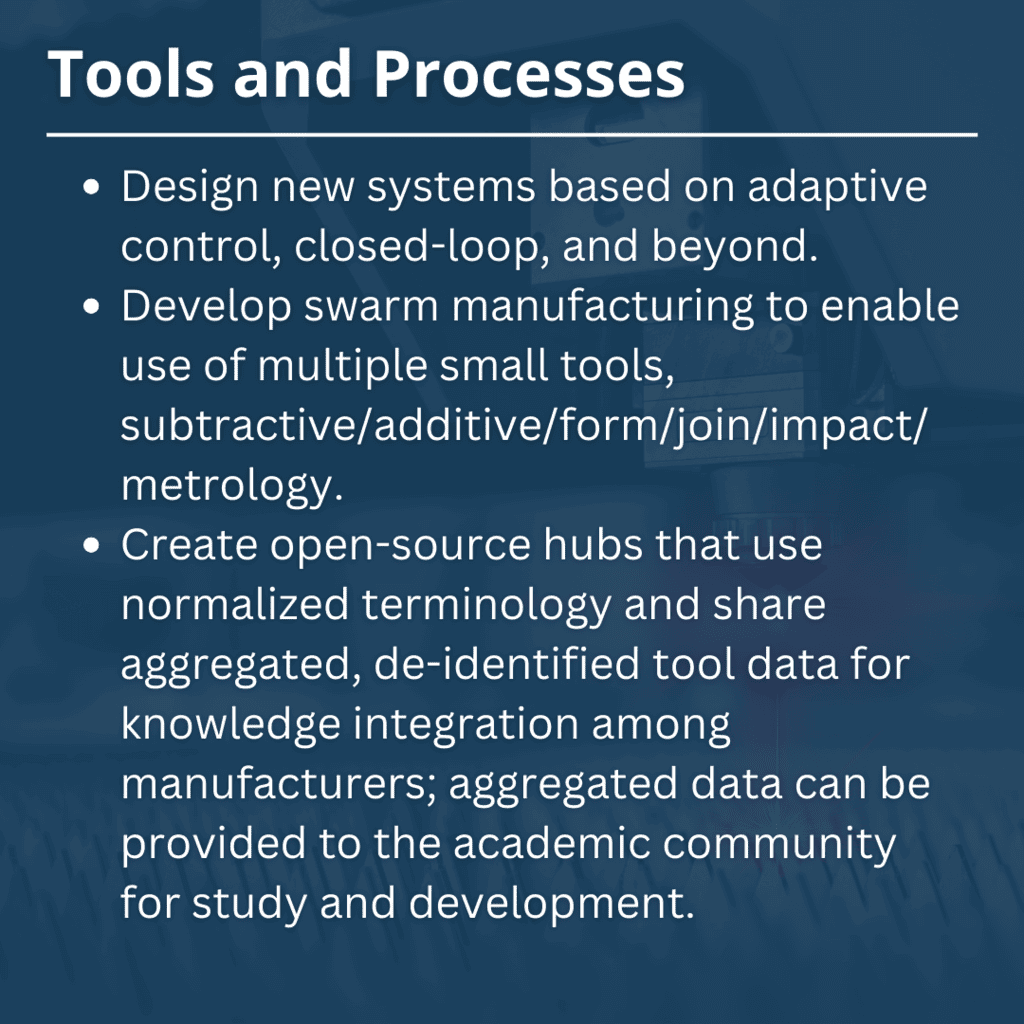

Current and future research should generate rapid innovation that enables the United States to lead in advanced manufacturing. Developing and implementing critical technologies in materials and supply chains; tools and processes; and data collection and measurement will enable manufacturers of all sizes to operate efficiently and safely both in normal and exceptional conditions.

Research into the following five overarching areas should generate rapid, sustained innovation that enables the United States to lead in advanced manufacturing.

1. Engineer new, sustainable materials for use in advanced manufacturing.

2. Enable new business models that better manage supply chains to build resilience, minimize disruption, and reduce wasted time and materials.

3. Design next-generation machines that are small, agile, and reconfigurable.

4. Create common, effective, and affordable standards for data collection, analysis, and communication.

5. Develop greater connectivity across the sector and work to eliminate silos.

Engineering research can help change U.S. manufacturing's negative trajectory by integrating research that improves current materials, tools, and processes with new manufacturing technologies and interoperable data-driven decision-making. Engineering research can also play a key role in attracting the next generation of manufacturing professionals as they recognize the complexity of the 21st-century manufacturing industry. This report aims to inspire researchers and funders (public, private, and nonprofit) to support and pursue these engineering research priorities.